I2c Seven Segment Drivers For Mac

In this instructable, I will be teaching the basics of multiplexing 7 segment displays using an Arduino and a couple of shift registers. This project is well suited for displaying numerical information or if you want to control a bunch of LEDs. For beginners, like me, I had no clue on how to tackle this project. But after trial and error and blood, sweat, and tears, I can say that I have a better understanding of multiplexing and how best to implement it on an Arduino. First off, what is multiplexing? What about Charlieplexing?

Any differences? Actually, they are they same Charlieplexing just takes multiplexing to a higher level. Both are techniques used to not only reduce the number of microcontroller pins needed, but also to reduce the power requirements substantially. However, at the cost of time and/or brightness.

In multiplexing, an entire digit or row of LEDs are shown at one time. After some time, the whole digit or row is turned off and the next digit/row is turned on, etc Simple! However, Charlieplexing is a bit more complicated in that it goes deeper than multiplexing. Instead of turning on a whole digit or row, a single segment or individual LED is turned on/off. After some time, the segment/LED is turned off and the next segment/individual LED is turned on, etc After cycling through a digit/row, the process repeats with the next digit/row. So, if you’re charlieplexing a 7-segment, you would consume a max of 20mA vs 160mA in multiplexing since only 1 segment is on at a time. The severe downside is that it takes longer to display information and brightness is reduced because the program needs to cycle through all the 7 segments + decimal or each LED first before moving to the next digit or row.

You will also notice a slight flicker as you chain more displays/LEDs. Look above for a comparison on multiplexing and charlieplexing. Notice how charlieplexing requires more time to display a number? Before you tackle your multiplexing project, you must lay everything out–research as much as you can. Otherwise, you will end up wasting time, money, and pulling your hair out of frustration. Step 1: Plan the hardware. To multiplex 7 segment displays, you will need the following: 1.

7 segment displays — I’m using 3 x 4.0 Inch Super Red 7 Segments from Kingbright (SA40-19SRWA) I strongly suggest you purchase COMMON ANODE displays. Common anode means all the anodes (+) pins are connected. You apply + voltage to the anode and use shift registers to ground the segments and form a complete circuit. However, with common cathode, all the ground (-) pins are connected. You then use shift registers to divert power to the anodes of the segments. However, the problem with this setup, as I’ve learned the hard way, is that you need to worry about sourcing AND sinking current.

I2c Seven Segment Drivers For Mac Pro

Most uControllers and shift registers cannot source nor sink a lot of current. Otherwise, you’d burn it out. If you require more voltage or current, you’ll then need to worry about transistors or darlington arrays (external drivers) since you’re using shift registers to tell them which segments need power (high voltage or current) and when to ground it. In other words, the hardware and code get more complicated and drives up cost. Microcontroller I strongly suggest getting an Arduino. The environment is much more intuitive and there is a huge pool of resources out there if you get stuck.

If you’re prone to making mistakes, get the Ruggeduino. It’s only $10 more than Arduino Uno and protects you and your precious uController from stupid mistakes. Serial-In Parallel-Out Shift Register If you have the money, buy from the TPIC6x595 or TPIC6x596 family of shift registers by Texas Instruments.

I2c Driver Download

I use the TPIC6 B596 in this instructable. The difference between its siblings (A, B, and C series) is the current handling capacity. In addition, the 596 family provides better reliability in cascading applications. When choosing shift registers, always make sure you do not exceed their current-handling limits. Side notes: – I would avoid the popular 74HC series as it can only source/sink a max of 70mA through the chip and cannot handle high voltages.

– I would also avoid using the common cathode / MAX7219/7221 setup with high voltage displays. Trust me It’s not worth it! You don’t want to know the trouble I’ve been through with this setup. Even though there’s a good library out there, it’s best to understand and have control of the underlying mechanism behind shift registers and multiplexing. Regulated DC Power Adapter If you’re planning to drive high-power displays, consider buying an regulated dc adapter that is greater than the forward voltage of your display.

A regulated DC adapter provides stable voltage under any load. Just make sure its current rating is greater than what’s required. In most cases, ratings higher than 500mA are enough (higher is better). Resistors You always need resistors to turn down current going through the LEDs. The formula for calculating required resistor is: (Supply Voltage – Minimum or Typical Forward Voltage per segment) / Desired forward current in Amps Note that the desired current should always be a bit less than the absolute maximum forward current stated in the datasheet in order to extend the life of the LEDs. Don’t forget that you need to do a separate calculation for the decimal point which may have a lower forward voltage requirement. Also, be careful with datasheets of large displays.

If they show low forward voltages (.

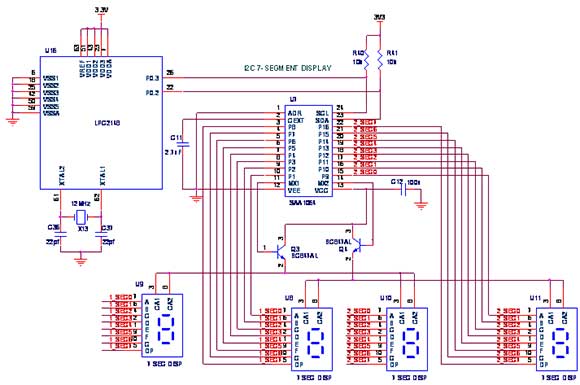

This project is an extension of my previous module. The new display features eight 7-segment displays arranged in two rows of four digits.

The on-board MAX7219 driver enables you to easily add eight 7-segment LED displays to your project using only 3 I/O pins of microcontroller. The major advantage of using this board is the time-division multiplexing operations required for continuous refreshing of the display digits are performed by the MAX7219 chip, thereby keeping the microcontroller free for doing other pressing tasks.

It is suitable for displaying two variable values simultaneously in a project, such as displaying temperature and humidity, or current and voltage, etc. Key Features:. based on MAX7219 display driver. SPI interface (3 pins). operates at +5V supply. individual control of all digits and decimal points. display brightness control through software.

I2c Seven Segment Drivers For Mac

dimensions 1.95″ x 1.95″ (50mm x 50mm). two 0.36″ 4-digit seven segment LED display The circuit diagram of this project is very simple (shown below) and derived from the datasheet of the MAX7219. In the above board, digits from right to left in the first row are DIG0 through DIG3, whereas in the second row, the digits from right to left are DIG4-DIG7. The following example code is written in C and compiled with mikroC Pro for PIC compiler to illustrate how to interface this display module with the.

The program is for a dual 4-digit decimal counter. The first row of the display will be an up counter counting from 0000 to 9999 with one second duration.

Meanwhile, the second row will count in reverse order from 9999 to 0000. The microcontroller used in the PIC12F board is PIC12F683. The details of MAX7219 registers and their initialization is described in my previous article.